Stick welding, also known as shielded metal arc welding (SMAW), is one of the most widely used welding processes in industries today. Its versatility and effectiveness in various conditions make it a favorite among welders. However, mastering stick welding requires knowledge, skill, and practice. Whether you're a novice or an experienced welder, understanding the basics and overcoming common challenges is key to achieving professional-quality welds. In this guide, we'll answer the most frequently asked questions about stick welding, covering electrodes, techniques, and troubleshooting.

I. The Basics of Stick Welding

Stick welding uses a consumable electrode coated with flux to create an electric arc that melts the base metals and joins them together. The flux coating protects the weld from atmospheric contamination, making it ideal for outdoor and windy conditions. Stick welding is commonly used for:

Repairing and maintaining equipment and pipelines

Fabrication of structures

Welding various metals and alloys, including carbon steel, stainless steel, cast iron, and hard-facing materials

II. Frequently Asked Questions About Stick Welding

1. What are the most common stick electrodes, and how do I choose the right one?

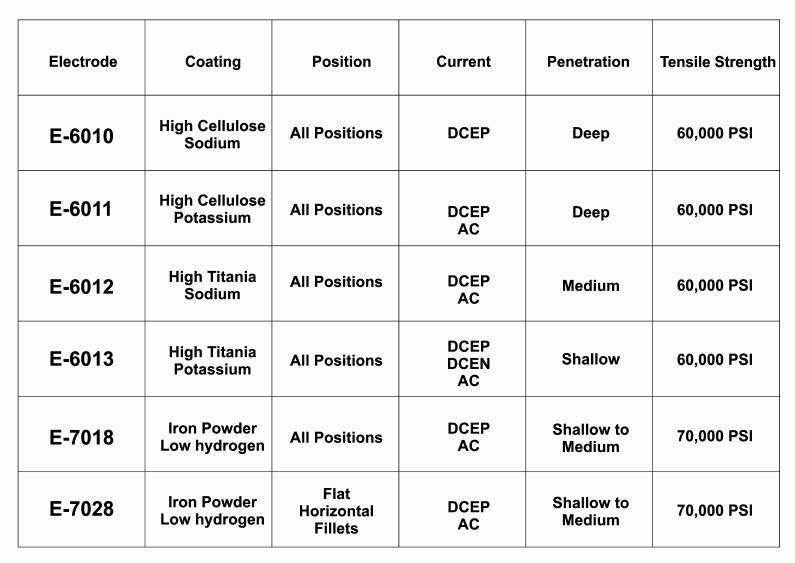

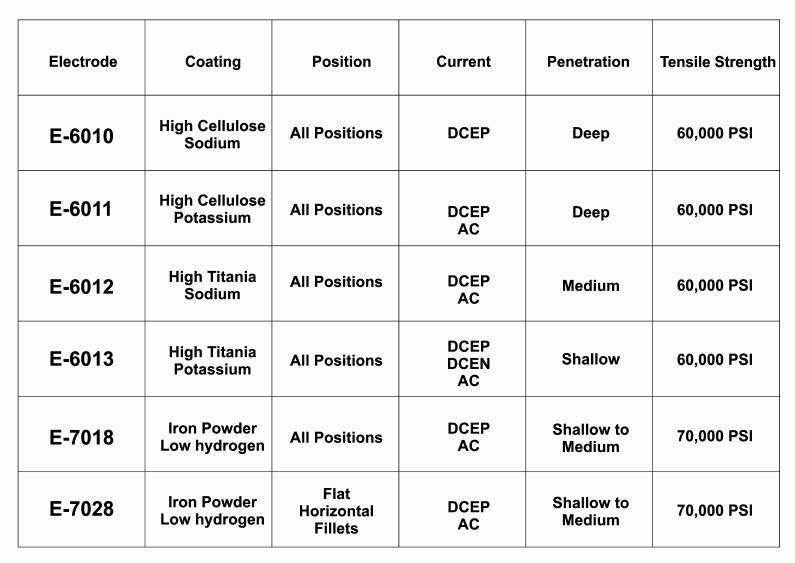

There are hundreds of stick electrodes available, but the most popular ones fall into the American Welding Society (AWS) A5.1 Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding. These include the E6010, E6011, E6012, E6013, E7014, E7024, and E7018 electrodes.

E6010: Ideal for root passes or joint penetration.

E6011: Suitable for flat and horizontal welding positions.

E6013: Offers a smooth, flat weld bead for thin materials.

E7018: A low-hydrogen electrode for high-strength, low-alloy steels.

E7024: A self-shielding electrode for high-speed welding.

Choosing the Right Electrode:

Match the electrode strength to the base metal.

Consider the welding position and joint design.

Ensure the electrode can provide good penetration and resistance to cracking.

2. What do AWS classifications mean for stick electrodes?

The AWS uses a standardized classification system to identify the properties and performance of stick electrodes. The classifications are printed on the sides of the electrodes and consist of numbers and letters. For example, E7018 breaks down as follows:

E: Indicates it's an electrode.

70: Minimum tensile strength of the weld (70,000 psi).

1: Welding position (all positions).

8: Coating type (low hydrogen, AC/DC reverse polarity).

Understanding this classification system helps you choose the right electrode for your application.

3. How do I select the right stick electrode?

The choice of electrode depends on:

Base Metal Type and Thickness: Match the electrode strength to the base metal. For example, use E7018 for low-alloy steels subjected to high-impact loads.

Welding Position: Choose electrodes suitable for flat, horizontal, vertical, or overhead welding.

Joint Design: Use E6010 or E6011 for root passes and E7018 or E7024 for cover passes.

Service Conditions: Select electrodes that resist cracking and corrosion, such as E309 or E316 for stainless steel.

4. What are the best practices for stick welding?

The settings and techniques for stick welding vary depending on the electrode, base metal, and welding position. Here are some general tips:

Current Settings: Adjust the welding current based on the electrode diameter and base metal thickness. Use lower currents for thinner metals and higher currents for thicker ones.

Arc Length: Maintain a short, consistent arc (about the diameter of the electrode). A shorter arc provides deeper penetration.

Electrode Angle: Hold the electrode at a 15-30° angle from the workpiece. A steeper angle increases penetration.

Travel Speed: Move steadily to avoid excessive melting or lack of fusion. Faster speeds produce thinner beads.

Manipulation: Use weaving or straight motion for better control.

Pro Tip: Always test your settings on scrap metal before welding the actual workpiece.

5. What are the best practices for stick welding different metal thicknesses?

Thin Metals (<1/4 inch):Use lower amperage, smaller electrodes (1/8 inch), and tack welding.

Medium Thickness (1/4–1/2 inch): Balance amperage and electrode size for proper penetration.

Thick Metals (>1/2 inch): Increase amperage, preheat, and use a weaving technique.

Pro Tip: Allow cooling between passes to prevent distortion.

6. What are the most common problems in stick welding, and how can I fix them?

Stick welding can encounter various problems that affect the quality and appearance of the weld, such as porosity, slag inclusions, lack of fusion, cracking, distortion, and spatter. These problems can be caused by improper electrode selection, incorrect welding settings, poor welding techniques, or unfavorable welding conditions.

Some tips and tricks to avoid or fix common stick welding problems are:

Prevent porosity by using a fresh and dry electrode, removing any rust, oil, paint, or dirt from the base metal, and avoiding excessive arc length or travel speed.

Avoid slag inclusions by using the correct electrode angle and travel speed, chipping and brushing the slag between passes, and filling the crater at the end of the weld.

Ensure good fusion by using the appropriate welding current and arc length, maintaining a tight fit-up and a small root opening, and using a backstep or backhand technique for starting the weld.

Prevent cracking by using a low hydrogen electrode, preheating and post-heating the base metal, avoiding rapid cooling or quenching of the weld, and minimizing the weld restraint and residual stress.

Minimize distortion by using a proper joint design and welding sequence, clamping and tacking the workpiece securely, welding in opposite directions or from the center outwards, and applying intermittent or staggered welds.

Reduce spatter by using a smooth and stable arc, adjusting the welding current and arc length, using an anti-spatter spray or gel, and cleaning the electrode holder and cable connections.

III. How to Choose the Right SMAW Welding Machine for Sale

Selecting the right SMAW welding machine is essential for achieving professional-quality welds. Here are the key factors to consider:

Amperage Range: Look for a machine with adjustable settings to handle different electrode sizes and base metal thicknesses.

Duty Cycle: A higher duty cycle allows for longer welding sessions without overheating.

Electrode Compatibility: Ensure the machine supports the electrodes you commonly use.

Portability: For on-site jobs, choose a portable stick welding machine.

For the best SMAW welding machine price, visit Megmeet ST400/500/630A Series Manual Arc Welding Machine and explore our high-quality options.

Conclusion

Stick welding is a powerful and versatile technique that requires skill, knowledge, and practice to master. By understanding electrode selection, proper techniques, and how to address common challenges, you can achieve high-quality welds in any situation. Whether you're working on thin sheets or thick plates, the right tools and techniques will make all the difference.

For expert guidance and the best SMAW welding machine for sale, trust Megmeet Welding Technology. Contact us today to take your welding skills to the next level.

Related articles:

1. AC Vs DC Stick Welding – Which One Is The Best & Why?

2. How to Improve Your Stick Welding Technique?

3. All You Need To Know About Overhead Stick Welding

4. Pros and Cons of Stick Welding and MIG Welding

5. What is the Difference Between Stick Welding and MIG Welding?