I. Product - brake shoes

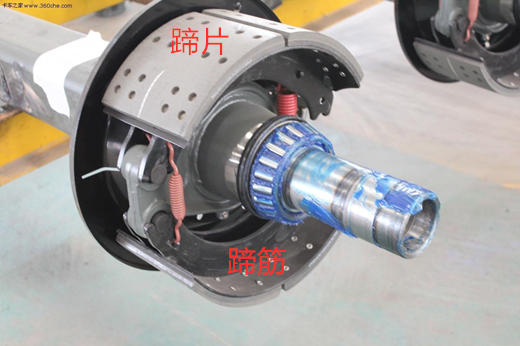

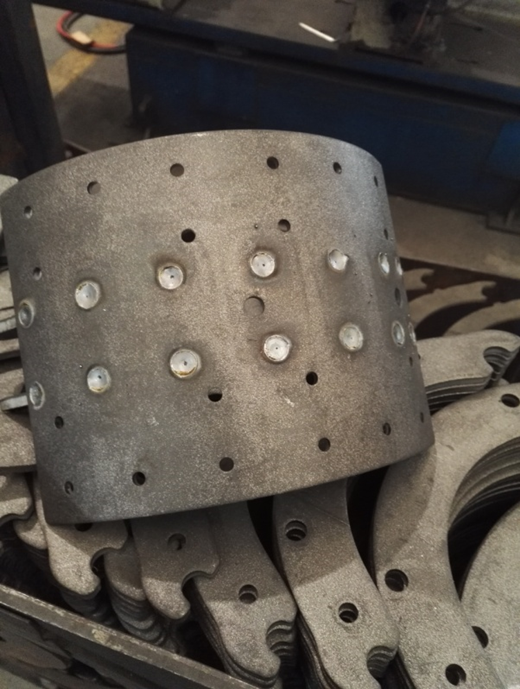

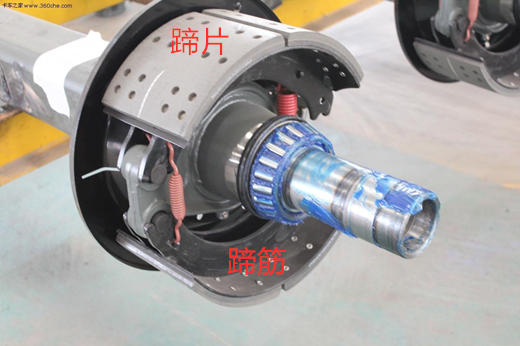

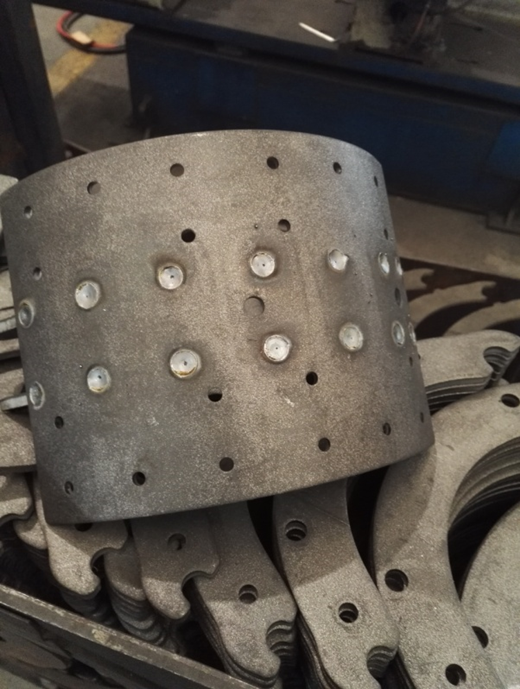

The product to weld is brake shoes for drum brake systems, which are widely used for truces of rear wheel drive. 6-8mm in thickness. Filling welding through pre-processed holes of 15mm to join the disc and the supporting structure underneath.

II. Customer - FUWA Group

The FUWA Group was founded in 1997. It has developed and become a leading manufacturer of exiles and chassis components for commercial vehicles like trucks, trailers, and engineering vehicles. FUWA has penetrated China and the Asian markets with FUWA, into the European market with VALX, into the North American market with AXN, and into the Australian market with K-Hitch products. Products of FUWA include axles for various heavy-duty vehicles, shipping containers, chassis systems, components, etc.

III. Technical Challenge of Brake Shoes Welding

The brake shoes consist of a friction plate, which is 6-8mm in thickness, and a stiffener underneath. A series of positioning holes are used as joints through plug welding. To achieve a higher production capacity, the end users intended to develop a special-purpose automatic system with 2 power sources for synchronous welding.

1)The depth of penetration, strength, and size of each weld are requested to be consistent. Defectives like cracking, undercut, and incomplete fusion are not allowed by FUWA.

2)No welding spatter is allowed on the surface of the brake shoes. There is no grinding and polishing process after welding. The request for the final welding performance is critical.

3)2 welding power sources with 2 torches are synchronized to weld automatically. The welding voltage, current, and wire-feeding speed have to be consistent.

4)Designed to weld for 24 hours/day, 7 days/week. The welding power sources are requested to be extremely durable and stable.

Brake Shoes: the Finished Product

Design of Brake Shoes

IV. MEGMEET Welding Equipment and Solutions

MEMGEET Ehave CM500H MIG/MAG Welder was recommended to work with 1.2 solid wire, C02 gas, and the function of spot welding at a current of 300A~350A.

1)Ehave CM500H was designed with full digital control and inverter technology. The duty cycle reaches 100% at the maximum output of 500A at 40 OC.

2)Ehave CM500H welds with high amperage for high deposition efficiency. The welding arc is stabilized, concentrated, powerful in penetration, and low in spatter.

3)The function of Spot Welding guarantees high consistency in operating time and welding performance. Unqualified welding results and production efficiency caused by inconsistent beats are successfully solved for the 2-welder system.

4)To reach the same depth of penetration, Ehave CM500H works with a welding current 15%~20% lower than conventional competitors. It ensures much better control of heat input and heat deformation.

5)Thanks to droplet inspection and micro-control technology, Ehave CM500H solved the problem of oversized wire tips after the welding stopped. The long-time and continuously successful arc ignition, and welding result of high quality and consistency become possible.

6)The digital control and anti-interference technology supports Ehave CM500H to stably generate high-quality welding in tough working environments of high temperature, power fluctuation, power surge, and radiation of high-frequency conduction.

Results of Spot Welding (Surface)

Welding Results (Inner Side)

V. Comparison of Welding Result

The 2 units of Ehave CM500H have high consistency in welding results thru 2 individual welding torches and an automatic system. Production efficiency has been increased by 50%. The welding arc and energy were centralized to reach desirable and consistent penetration depth. Heat input was 20% lower than the previous solutions. The heat distortion was therefore strictly limited. Spatter was also well controlled. Long-time and continuous production with shifts has been ensured with high reliability.

IV. Application of Ehave CM500H MIG/MAG Welding Machine