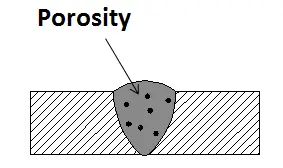

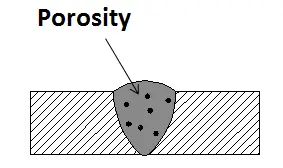

Welding porosity is a common defect encountered during welding, characterized by gas holes formed in the weld metal. These pores not only compromise the strength and quality of the weld but can also lead to leaks or fractures in welded structures. Therefore, a deep understanding of the causes, impacts, and methods for addressing porosity in welding is essential for improving welding techniques and ensuring welding quality. This article will provide a detailed analysis of all aspects of welding porosity to help welding engineers and technicians better understand and tackle this issue.

I. Causes of Welding Porosity

Welding porosity can arise from a variety of factors, primarily categorized as follows:

1) Influence of Welding Materials:

The quality of welding materials directly affects the welding outcome. Contaminants such as oil, rust, or oxides present on the surface of welding wires, rods, flux, or base materials can release gases during welding, resulting in porosity in welding. Additionally, a mismatch in the chemical composition of the welding wire and base material may also lead to pore formation. Therefore, it is crucial to select appropriate welding materials and thoroughly clean and dry them before welding.

2) Influence of Shielding Gases:

Shielding gases play a critical role during the welding process by protecting the arc and the molten pool. If the purity of the shielding gas is insufficient or if its flow is unstable and affected by wind, it can compromise the effective protection of the molten pool, allowing atmospheric gases like oxygen and nitrogen to enter the pool, leading to porosity. Consequently, choosing the right shielding gas, controlling its flow and pressure, and implementing wind protection measures are key to preventing porosity in welding.

3) Influence of Welding Processes:

Choosing the right parameters for the welding process significantly impacts welding quality. Incorrect selections or non-standard operation of parameters such as welding current, voltage, arc length, welding speed, and torch angle can destabilize the arc and affect the flow of the molten pool, preventing gases from escaping promptly, and thus causing porosity. To avoid such situations, it is essential to select appropriate welding process parameters according to the specific welding method and object, adhering strictly to standardized operational protocols.

4) Influence of Welding Environment:

The conditions of the welding environment also affect pore formation. Fluctuations in temperature, humidity, and atmospheric pressure, or inappropriate bevel shapes, gaps, and positioning of welded parts can influence the cooling rate of the molten pool and the uniformity of contraction, altering gas solubility and leading to porosity. Therefore, striving for a stable welding environment and designing and assembling welding components appropriately are vital measures to reduce the risk of porosity in welding.

II. Impacts of Welding Porosity

The presence of welding porosity can impede welding quality and performance in several ways:

1) Reduced Weld Strength:

Porosity defects directly diminish the strength of the weld, potentially causing structural failure during load-bearing scenarios, which can have severe repercussions for critical components.

2) Decreased Corrosion Resistance:

Porosity defects can lower the corrosion resistance of welds, particularly in chemically corrosive environments, where pores may serve as initiation sites for corrosion, accelerating deterioration.

3) Aesthetic Impact on Welds:

Pores can detract from the weld's appearance, affecting its overall quality and market competitiveness.

4) Increased Difficulty in Post-Weld Treatment:

Existing porosity in the weld may necessitate corrective repairs or re-welding, leading to increased production costs and time, thus reducing overall efficiency.

III. Solutions to Welding Porosity

To address the various causes of welding porosity, the following methods can be employed:

1) Preheating and Post-Heat Treatment:

Preheating can minimize the temperature gradient at the weld site, decrease gas solubility, and facilitate gas escape. Post-heat treatment can relieve residual stress in the weld and enhance its microstructure and properties, thus mitigating the effects of porosity. The temperatures and durations for preheating and post-heat treatment should be selected and controlled based on the specific welding materials and methods.

2) Using Active Gases or Pulsed Laser Welding:

Active gases can chemically react with gases in the molten pool to form compounds that are easier to expel, thus reducing pores. Pulsed laser welding can alter the behavior of the molten pool, minimizing the entrainment of shielding gases into small pores and consequently reducing or eliminating the occurrence of pores in welding.

3) Employing Beam or Arc Oscillation Techniques:

Utilizing beam or arc oscillation can enhance the fluidity of the molten pool, promoting gas expulsion while improving the formation and filling qualities of the weld, effectively reducing the formation of pores in welding.

4) Repairing or Re-Welding:

In cases where porosity has already occurred within the weld, repair or re-welding methods can be employed to eliminate or reduce the size of the pores. Repair involves re-welding at the site of the pore, using filler wire or flux to fill in the defects, while re-welding consists in redoing the entire weld to address multiple defects or major issues. Re-welding is typically used when there are numerous pores or when they are located in critical areas of the weld.

5) Strengthening On-Site Control and Management:

It is crucial to enhance the control of the welding environment and ensure adherence to operational protocols during the welding process. In conditions of high wind speed or humidity, employing windbreak measures or conducting environmental monitoring can help maintain the quality of the shielding gas. Furthermore, establishing comprehensive welding operational procedures and inspection systems ensures that welders follow specified parameters and procedures, helping to minimize porosity production.

6) Choosing Appropriate Welding Equipment and Techniques:

The choice of welding equipment is another significant factor affecting the occurrence of welding porosity. Utilizing suitable welding machines, shielding gas flow control devices, and welding fixtures can enhance welding quality. Exploring more advanced welding methods, such as TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding, can offer better control over the molten pool and consequently reduce the formation of porosity.

Conclusion

Welding porosity is a prevalent and severe defect in the welding process, adversely affecting the strength, corrosion resistance, and overall safety of welded structures. Understanding the causes and impacts of welding porosity, as well as effective solutions, is vital for enhancing welding technology and ensuring product quality. Therefore, in practice, emphasis should be placed on the selection of welding materials, management of shielding gases, optimization of process parameters, and control of the welding environment to minimize the occurrence of porosity, ultimately improving welding quality and ensuring the safety and reliability of welded structures.

Through the implementation of reasonable preventive measures, strict operational protocols, and efficient welding techniques, the issue of welding porosity can be effectively controlled and resolved, providing a better foundation for the development of the welding industry. By adopting these strategies, organizations can significantly enhance productivity while reducing defects, thereby fostering a culture of quality in welding applications.

Related articles:

1. Porosity in Welding: Causes, Types, Effects and Solutions

2. How to Avoid Porousness in TIG Welds?

3. Common Electrical Welding Machine Defects and Solutions

4. What Are Welding Beads? (types, functions, techniques & defects)

5. Types of Welding Defects in Shipbuilding and Their Remedies