Welding beads are the backbone of any successful welding project, serving as critical indicators of weld quality and structural integrity. This guide will delve into the world of welding beads, exploring their definition, formation, types, and real-world applications. Whether you're a seasoned professional or an industry newcomer, this article will provide you with the knowledge to optimize your welding processes.

I. What are welding beads?

A welding bead is the metallic seam formed along the joint during the welding process. It is created by depositing filler material into the joint, which then solidifies to form a strong bond between the two metal pieces. The characteristics of a welding bead—such as its shape, size, and appearance—are influenced by factors like the type of metal, welding technique, equipment settings, and operator skill.

Key Factors Influencing Welding Beads:

Material Type and Thickness: Different metals and thicknesses require tailored approaches.

Welding Process: Techniques like MIG, TIG, or arc welding yield varying bead characteristics.

Equipment Settings: Voltage, current, and wire feed speed significantly impact bead formation.

Operator Technique: The movement and angle of the torch or electrode play a crucial role.

II. What are the different types of welding beads?

Understanding the different types of welding beads is essential for selecting the right technique for your project. Below are the most common types:

1. Stringer Beads

Description: Straight and narrow beads formed by moving the torch or the electrode in a straight line along the joint, with little or no side-to-side movement.

Applications: Ideal for thin or heat-sensitive metals, vertical or overhead welding positions.

Advantages: Fast welding, minimal heat input.

Use Cases: Multi-pass welding for deep or wide joints.

2. Weave Beads

Description: Wide and flat beads created by moving the torch or the electrode in a side-to-side motion along the joint, while advancing forward at a steady pace.

Applications: Thick or hard-to-fuse metals, horizontal or flat welding positions.

Advantages: Better penetration and heat input, suitable for single-pass coverage of large areas.

Use Cases: Bridging gaps between metal pieces.

3. Whip Beads

Description: Short and intermittent beads formed by moving the torch or the electrode forward and backward along the joint, while advancing forward at a slow pace.

Applications: Primarily used in stick welding to control weld pool size and prevent overheating.

Advantages: Helps maintain consistent weld pool shape and prevents burn-through.

Use Cases: Shielded metal arc welding (SMAW), help to control the size and shape of the weld pool, as well as to prevent overheating and burn-through of the base metal.

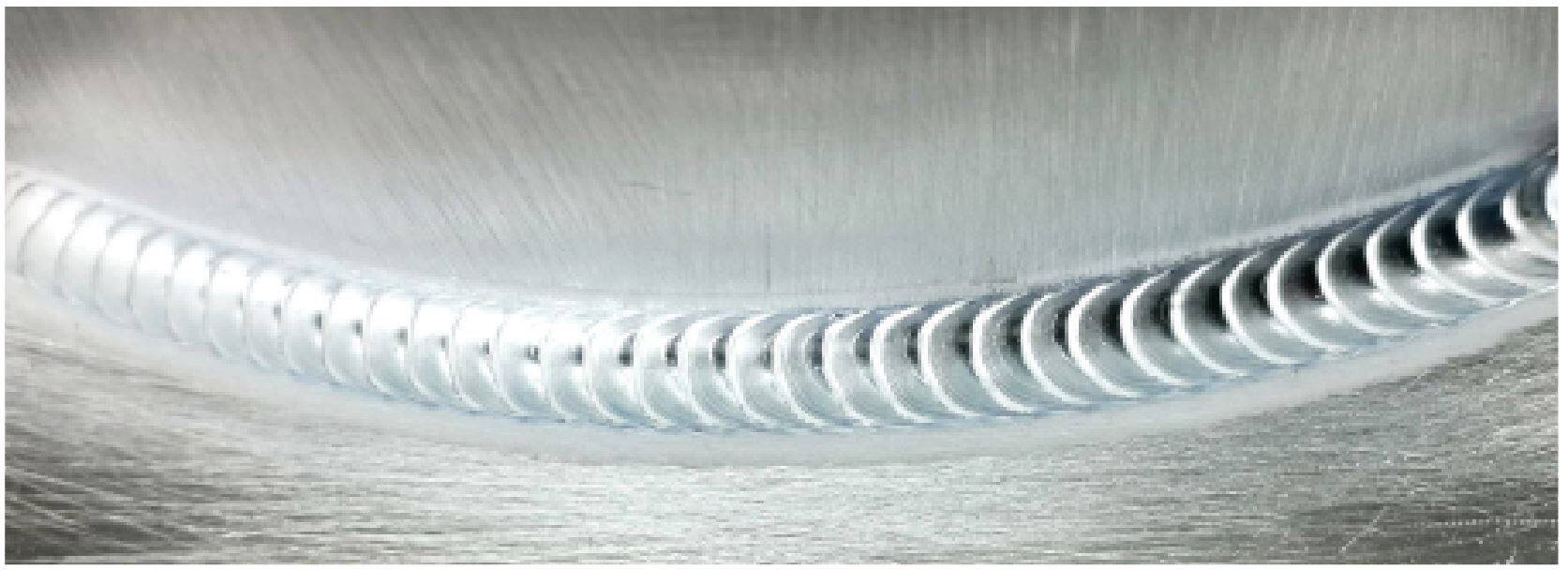

4. Walking the Cup Beads

Description: Circular or spiral weld beads that are created by moving the torch or the electrode in a circular motion along the joint, while resting the cup or the nozzle of the torch or the electrode on the base metal. They are mainly used for TIG welding.

Applications: Requires a non-consumable tungsten electrode and separate filler rod.

Advantages: Ensures steady and consistent arc length and torch angle, producing smooth, uniform beads.

Use Cases: High-precision projects requiring clean, oxide-free welds.

IV. Quality Standards for Welding Beads

A high-quality welding bead should exhibit:

Smooth and Uniform Surface: Free from cracks, porosity, and spatter.

Proper Penetration and Fusion: Complete blending of the bead with the base metal.

Consistent Dimensions: Uniform width and height along the joint.

V. Common Defects and Solutions

Even with proper technique, defects can occur. Here are common issues and their solutions:

1) Porosity: Caused by trapped gases.

2) Lack of Fusion: Incomplete blending of bead and base metal.

3) Surface Cracks: Often due to thermal stresses.

VI. Choosing the Right Welding Bead

For Thin Materials: Opt for Stringer or Whip beads to minimize heat input.

For Thick Materials: Weave beads provide deeper penetration and strength.

For Precision Projects: Walking the Cup beads ensure smooth, uniform results.

For High-Speed Production: Stringer beads are ideal for fast, efficient welding.

Conclusion

Welding beads are more than just aesthetic elements; they are critical to the structural integrity and quality of your welds. By understanding the types of welding beads and their applications, you can optimize your welding processes for better results. Megmeet Welding Technology is committed to providing cutting-edge solutions to meet the diverse needs of modern industries.

Related articles

1. Expert Tips for Achieving Seamless Welds: A Guide for Welding Perfection

2. What are the 4 Basic Welding Positions and How to Choose the Right One?

3. What protective gas should I use for laser welding?

4. Complete Basics of Gas Shielded Arc Welding

5. Shielding Gases for TIG & MIG Welding: which gas is best?