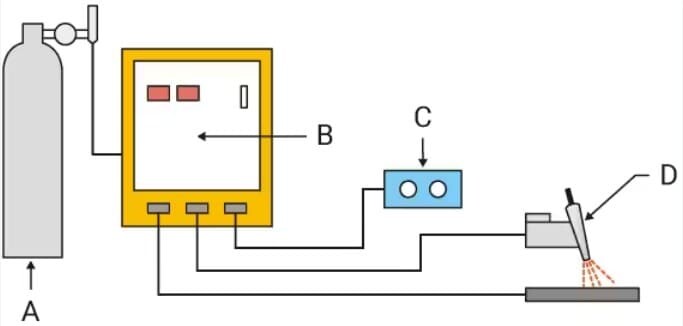

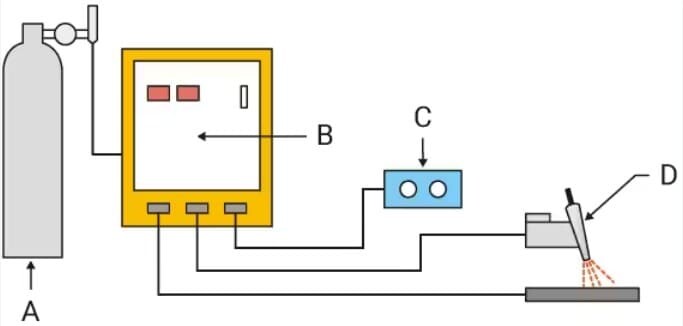

Tungsten Inert Gas (TIG) welding is a precise and efficient welding process used across industries for its high-quality welds. However, like any technical skill, it comes with its set of challenges. Understanding these common issues and their solutions is crucial for welders aiming for flawless results.

1. Tungsten Contamination

Issue: One of the primary issues encountered in TIG welding is tungsten contamination. This occurs when the tungsten electrode touches the molten weld pool, leading to contamination and defects in the weld.

Solutions: Sharpen the electrode correctly and maintain the appropriate electrode stick-out to prevent it from touching the workpiece.

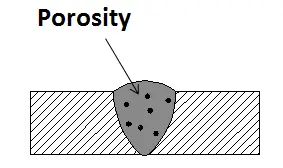

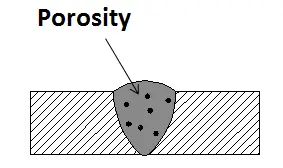

2. Porosity

Issue: Porosity, characterized by tiny bubbles or cavities in the weld bead, can weaken the weld. It often results from inadequate gas coverage or impurities in the base material.

Solutions: Ensure proper gas flow rates and shielding gas purity. Clean the base metal surface to remove contaminants.

3. Lack of Fusion

Issue: Lack of fusion occurs when the weld fails to bond properly with the base material. It can stem from incorrect welding parameters or inadequate heat input.

Solutions: Adjust the welding parameters, such as amperage, travel speed, and heat input to achieve better fusion. Properly prepare the joint edges for welding.

4. Cracking

Issue: Weld cracking can occur due to various factors, such as rapid cooling, high hydrogen levels, or excessive stress on the weld.

Solutions: Preheating the base material, controlling cooling rates, and using low-hydrogen filler materials can mitigate the risk of cracking.

5. Inconsistent Weld Bead

Issue: Inconsistent weld bead appearance often results from erratic movements or inconsistent feeding of the filler material.

Solutions: Maintaining steady torch manipulation and a consistent filler rod feed speed can help achieve a uniform weld bead.

6. Excessive Spatter

Issue: Spatter, the unwanted bits of molten metal, can create a messy weld and lead to rework.

Solutions: Properly cleaning the base metal, adjusting the shielding gas flow, and optimizing welding parameters can significantly reduce spatter.

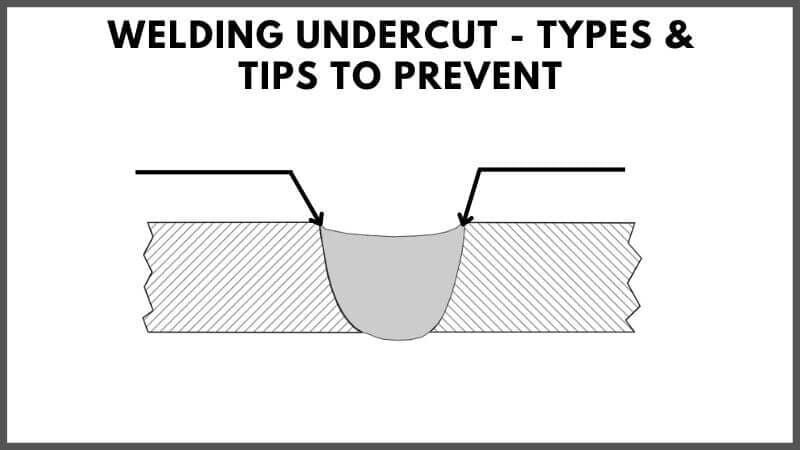

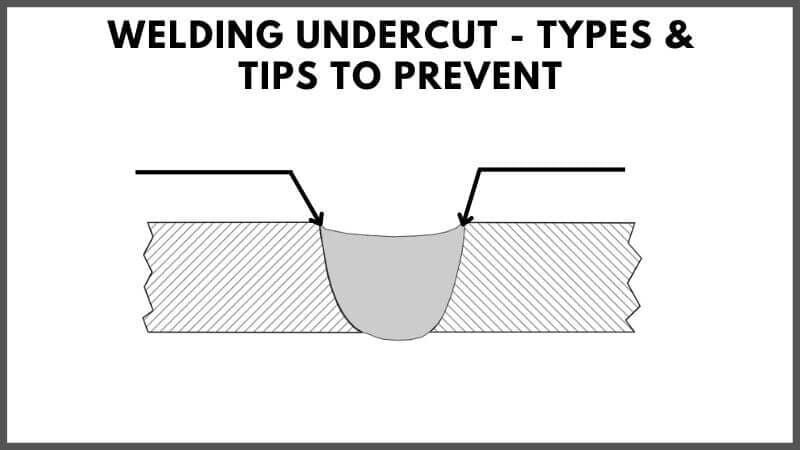

7. Undercutting

Issue: Undercutting is the groove formation along the base metal next to the weld bead, weakening the joint. It commonly arises from excessive heat or incorrect torch angle.

Solutions: Proper manipulation of the torch angle and control of the heat input can prevent undercutting.

8. Weld Discoloration

Issue: Weld discoloration, often seen as a change in the color of the weld, results from improper gas shielding or excessive heat input.

Solutions: Adjusting the gas flow, utilizing suitable filler metals, and controlling heat exposure can prevent discoloration.

9. Tungsten Electrode Erosion

Issue: Erosion of the tungsten electrode tip can lead to instability in the arc and inconsistent welds.

Solutions: Using the appropriate electrode size, maintaining the correct grinding angle, and utilizing proper amperage settings can prolong electrode life.

10. Proper arc length control:

Issue: Contamination of the weld due to foreign materials or residue on the base metal surface can compromise the weld integrity.

Solutions: Thoroughly cleaning the base metal and ensuring a clean working environment can prevent weld contamination.

These are some of the common TIG welding problems and their solutions. By following these tips and techniques, you can improve your TIG welding skills and produce high-quality welds on various metals. For more welding tips, welding guides, and professional welding equipment, you can follow the Megmeet News Center column or contact Megmeet Welding Technology.

Related articles

1. TIG Welding: A Guide to Top-Quality Connections

2. MIG/MAG, MMA, TIG Welding: Choosing the Right Technique

3. MIG VS TIG Welding: What are the Differences?

4. TIG Welding Stainless Steel: A Beginners Guide

5. TIG Welding: What is Scratch-Start, Lift-Arc and HF Ignition?