When it comes to welding, the options can seem overwhelming. From MIG to TIG to Arc welding, each technique has its own benefits and best-use scenarios. But fear not! In this article, we'll break down these different welding types in simple terms so you can understand the differences and choose the right one for your project.

I. Introduction

Welding is the art of joining materials together using heat and pressure. It's like creating a bond between pieces of metal, making them inseparable. But did you know there are different types of welding? Some are like precision surgery, while others are more like heavy-duty construction work. Let's dive into the world of welding and explore the differences between MIG, TIG, Arc welding, and more.

II. MIG Welding: The Beginner's Choice

MIG welding, or Metal Inert Gas welding, is like using a magic wand that effortlessly fuses metal. It's quick, efficient, and perfect for beginners. With MIG welding, a wire electrode is fed through a welding gun, melting into the base metal and creating a strong bond. It's like painting with metal!

1) Key Points:

Fast and efficient

Ideal for beginners

Produces clean welds

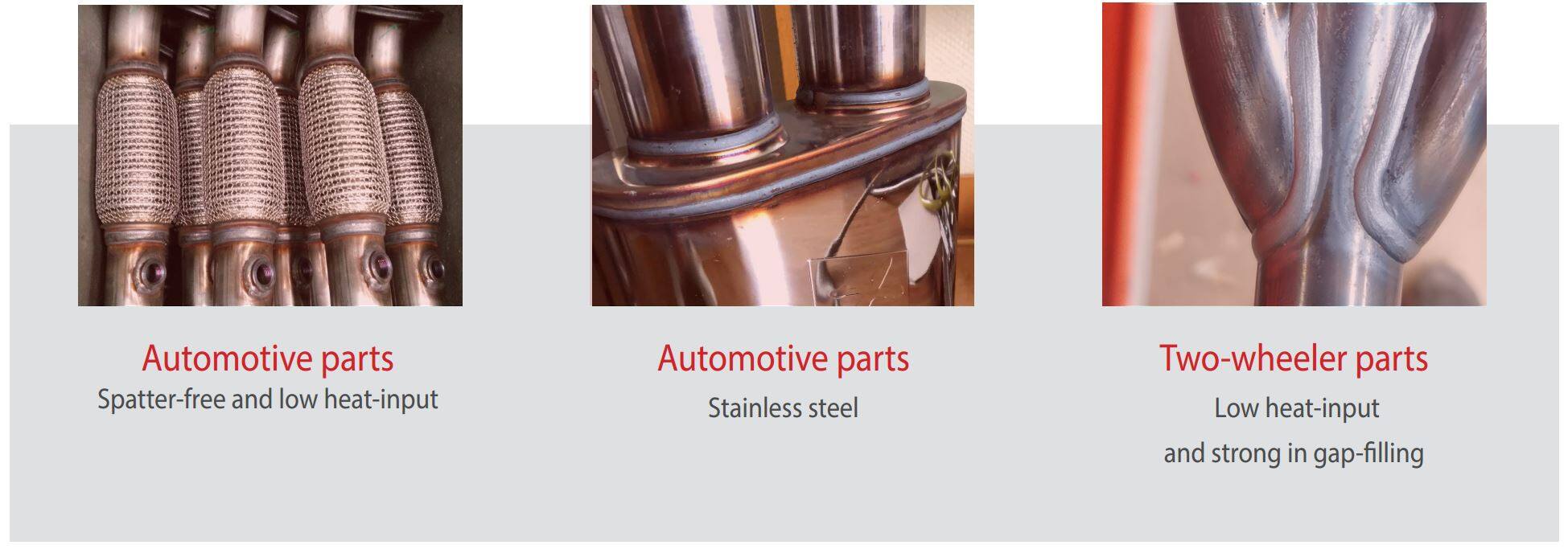

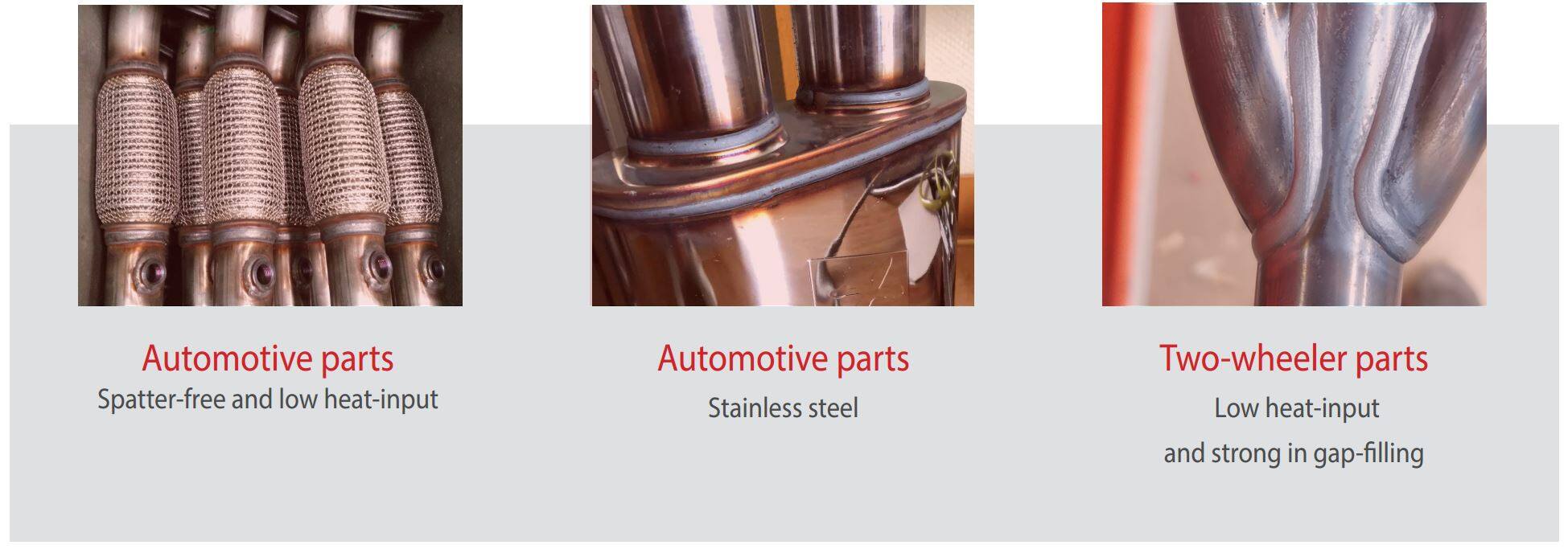

2) Applications:

III. TIG Welding: Precision at Its Best

TIG welding, or Tungsten Inert Gas welding, is the artisan's choice. It's precise, delicate, and produces beautiful welds that are as strong as they are elegant. In TIG welding, a non-consumable tungsten electrode heats the metal, while a separate filler rod is used to create the weld. It's like sculpting with molten metal!

effect.jpg)

1) Key Points:

2) Applications:

IV. Arc Welding: Old Reliable

Arc welding is the workhorse of the welding world. It's rugged, versatile, and can tackle almost any job thrown its way. With arc welding, an electric arc is created between the electrode and the base metal, generating intense heat that melts the metal and forms a bond. It's like wielding a lightning bolt to join metal together!

1) Key Points:

Versatile and rugged

Suitable for outdoor use

Can weld thick materials

2) Applications:

V. Comparison of Three Main Welding Types

| Welding Technique | Speed | Precision | Versatility | Ease of Use | Applications |

| MIG Welding | Fast | Moderate | High | Easy | Automotive repairs, fabrication, and general manufacturing. |

| TIG Welding | Slow | High | Moderate | Moderate | Aerospace, artistic welding, and precision fabrication. |

| Arc Welding | Moderate | Moderate | High | Moderate | Construction, shipbuilding, and heavy equipment repairs. |

VI. Other Welding Techniques

Apart from MIG, TIG, and Arc welding, there are several other notable welding techniques worth mentioning:

Stick Welding: Also known as Shielded Metal Arc Welding (SMAW), it's simple and portable, commonly used in construction and maintenance.

Flux-Cored Arc Welding (FCAW): Similar to MIG welding but uses a tubular wire filled with flux, ideal for outdoor welding in windy conditions.

Gas Welding: Uses a flame to heat the metal and a separate filler rod to create the weld, commonly used for repairs and fabrication work.

Laser Welding: It's the high-tech wizardry of welding. It's incredibly precise and fast, making it ideal for industries like automotive or electronics where precision is paramount.

Electron Beam Welding (EBW): It takes welding to the next level—literally. It's used in aerospace and other industries where strength and precision are critical.

Friction welding: It's like the strongman of welding. Instead of melting the metal, you generate heat through friction between the two pieces, then press them together to create a solid bond. It's fast, efficient, and produces welds with exceptional strength.

Plasma Arc Welding (PAW): It's like TIG welding on steroids. It uses a constricted arc and a high-velocity jet of ionized gas (plasma) to melt the metal. It offers even greater precision and control than TIG welding, making it ideal for aerospace and other high-tech applications.

Submerged Arc Welding (SAW): It's like the quiet achiever of welding techniques. It uses a granular flux to shield the arc and the molten weld pool, creating high-quality welds with minimal spatter. It's often used in heavy fabrication and welding of thick materials.

Resistance welding: It's like the silent ninja of welding. It uses electric resistance to generate heat and join the materials together. It's fast, clean, and produces welds without the need for filler metal, making it ideal for mass production.

VII. Conclusion:

So, there you have it! A rundown of some of the most common welding types out there. Whether you're a beginner looking to dip your toe into welding or a seasoned pro looking to expand your skills, there's a welding technique out there for you. So grab your helmet, fire up your machine, and let's get welding!

Related articles

1. Cold Metal Transfer (CMT) Welding VS. Retract Droplet Transfer (RDT) Welding

2. Pulsed vs. CW Laser Welding: Key Differences | Expert Insights

3. GMAW vs. CO2 Welding: A Comparison of Two Metal Arc Welding Processes

4. Laser Welding Vs. Arc (TIG) Welding

5. Traditional Welding vs. Laser Welding

FAQs on Welding Techniques

Q1: Which welding type is best for beginners?

A1: MIG welding is often recommended for beginners due to its ease of use and forgiving nature.

Q2: Can TIG welding be used for thick materials?

A2: While TIG welding is more commonly used for thin materials, it can also be used for thicker metals with the appropriate settings and technique.

A3: The primary differences between MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding lie in their techniques, applications, and the characteristics of the welding processes.

Q4: Is Arc welding suitable for outdoor use?

A4: Yes, Arc welding is suitable for outdoor use, making it ideal for construction and repair jobs conducted in open environments.

Q5: Are there eco-friendly variations of these welding methods available?

A5: Yes, there are eco-friendly variations and advancements within welding methods that prioritize environmental considerations. Some developments aim to reduce the environmental impact associated with traditional welding techniques. For example Cold Metal Transfer (CMT) Welding, Pulsed MIG (PMIG) Welding, Inverter-Based Welding Machines...

effect.jpg)