Arc welding is a process that uses an electric arc to join metal pieces together. The quality of the welds depends on various factors, such as the type of material, the welding technique, and the welding parameters. In this article, we will focus on three important welding parameters that can influence the weld penetration, the weld bead shape, and the weld defects: arc length, weld speed, and welding current.

I. What is Arc Length?

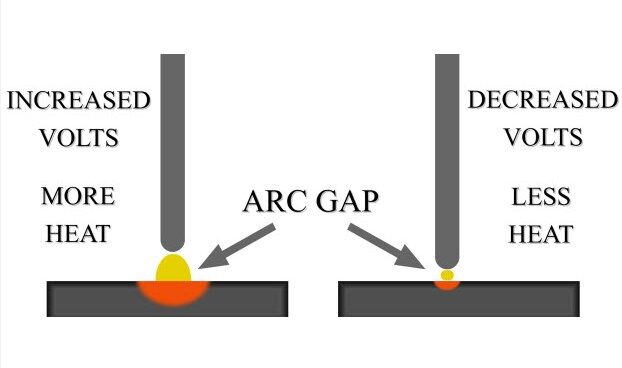

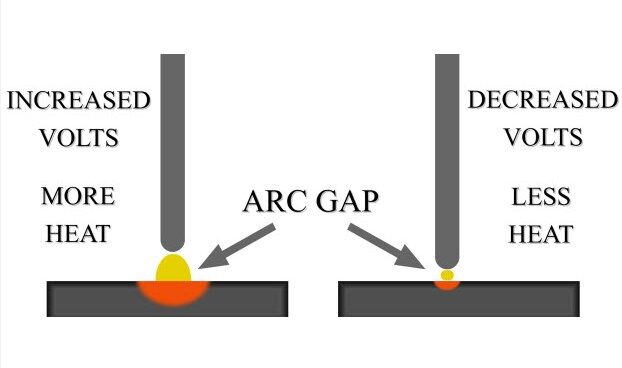

Arc length, also called arc gap, is the distance between the part that needs to be welded and the electrode tip. This distance can affect the stability of the arc, the weld current, and the concentricity of the part. If the arc length is too long, the arc will be unstable, and the weld current will be too low. This can result in poor fusion, spatter, and undercut. If the arc length is too short, the arc will be stable, but the weld current will be too high. This can cause excessive heat, burn-through, and distortion.

The optimal arc length depends on the type of welding process, the type of electrode, and the thickness of the material. In general, the arc length should be about the same as the diameter of the electrode. For example, if the electrode is 0.030 inches thick, the arc length should be around 0.030 inches as well.

II. What is Weld Speed?

Weld speed, also called travel speed, is the speed at which the welding torch moves along the joint. Weld speed can affect the heat input, the weld pool size, and the weld bead shape. If the weld speed is too slow, the heat input will be too high and the weld pool will be too large. This can cause excessive penetration, sagging, and porosity. If the weld speed is too fast, the heat input will be too low and the weld pool will be too small. This can cause insufficient penetration, cold lap, and lack of fusion.

The optimal weld speed depends on the type of welding process, the type of filler metal, and the thickness of the material. In general, the weld speed should be as fast as possible without compromising the weld quality. For example, the tube mill welding speed should be between 3 inches to 60 feet per minute, the lathe welding speed should be 5 to 60 inches per minute, and the orbital welding equipment weld speed should be 4 to 10 inches per minute.

III. What is Welding Current?

Welding current, also called amperage, is the amount of electric current that flows through the arc. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. If the welding current is too low, the heat input will be too low, and the metal transfer mode will be globular or short-circuiting. This can cause insufficient penetration, cold lap, and lack of fusion. If the welding current is too high, the heat input will be too high, and the metal transfer mode will be sprayed or pulsed. This can cause excessive penetration, spatter, and distortion.

The optimal welding current depends on the type of welding process, the type of electrode, and the thickness of the material. In general, the welding current should be proportional to the thickness of the material. For example, if the material is 0.030 inches thick, the average welding current should be around 30 amps.

IV. Conclusion

Arc length, weld speed, and welding current are three important welding parameters that can affect the quality of your welds. By understanding how they work and how to adjust them, you can improve your welding skills and achieve better results. Remember to always follow the manufacturer’s recommendations and the welding codes for your specific application.

Related articles:

1. Identifying and solving tungsten electrode and arc issues

2. Choosing the Right Shielding Gases for Arc Welding

3. How Does Arc Length Affect a Weld?

4. Welding Quality Assurance & Quality Control Processes

5. TIG Welding: A Guide to Top-Quality Connections